显示 497-509 个结果(共 509 个结果)

-

Installation instructions:

1.Unload the upper cover of control lead

2.Measure control lead depth,remove the excess part of connector lead and driving rod

3.Fit the control rod with full closed valve,turn the position plate to shut position

4.load upper cover

-

Series F180 butterfly valves designed to comply with MSSSP-67,BS5155 and API 609.

Compatible with GB,ANSI,DINBS,JIS flanges.

Characteristic of series F180 butterfly valve is to splice the rubber liner on the body,the strength more highlyand the seal more reliably for the seat.

There is O-ring casted onthe seal surface of the seat,negates need for flange gaskets.

Available in size 1 1/2″to 24″.

Available in wafer type,lug typeand U-section wafer type body.

Available with handles,manualgear operators,and electric or pneumatic actuators.

-

Series F180 butterfly valves designed to comply with MSSSP-67,BS5155 and API 609.

Compatible with GB,ANSI,DINBS,JIS flanges.

Characteristic of series F180 butterfly valve is to splice the rubber liner on the body,the strength more highlyand the seal more reliably for the seat.

There is O-ring casted onthe seal surface of the seat,negates need for flange gaskets.

Available in size 1 1/2″to 24″.

Available in wafer type,lug typeand U-section wafer type body.

Available with handles,manualgear operators,and electric or pneumatic actuators.

-

Series F180 butterfly valves designed to comply with MSSSP-67,BS5155 and API 609.

Compatible with GB,ANSI,DINBS,JIS flanges.

Characteristic of series F180 butterfly valve is to splice the rubber liner on the body,the strength more highlyand the seal more reliably for the seat.

There is O-ring casted onthe seal surface of the seat,negates need for flange gaskets.

Available in size 1 1/2″to 24″.

Available in wafer type,lug typeand U-section wafer type body.

Available with handles,manualgear operators,and electric or pneumatic actuators.

-

Series F203 butterfly valves designed to comply with MSS SP-67,BS5155 and API 609.

Compatible with GB.ANSI,DIN,BS,JIS flanges.

The seat of series F203 butterfly valve is designed into without back.

The tongue-and -groove seat is lower torque and field replaceable

There is O-ring casted on the seal surface of the seat,negates need for flange gaskets.

Available in size1″to 24″.

Available in wafer type,lug type body.

Available with handles,manual gear operators,and electricorpneumatic actuators.

-

Stainless steel wafer check valve PN40

-

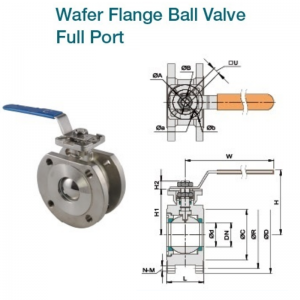

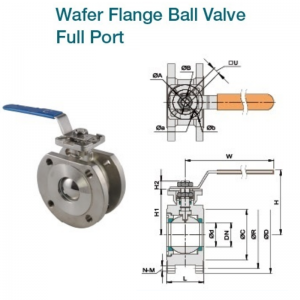

Stainless steel wafer flange ball valve full port

-

Design and Manufacture:JB/T8691,MSS SP-81

Face to face:GB/T15188.2,TAPPI TIS 405.8

Flange ends dimension:ANSI B 16.5,GB/T79-94

Inspection and Test:MSS SP-81,GB/T 13927

-

Design & manufacture: API 609,ASME B16.34

Testing inspection: API 598

Face to Face dimensions:ANSI 609

Flanged end dimension: ASME B16.5,ASME B16.47A,ASME B16.47B,MSS SP-44,API 605

Butt-Welded end dimension: ASME B16.25

-

Installation instructions:

1.Unload the upper cover of control lead

2.Measure control lead depth,remove the excess part of connector lead and driving rod

3.Fit the control rod with full closed valve,turn the position plate to shut position

4.load upper cover

-

Stainless steel Y check valve screw end PN40

-

Stainless steel Y strainer screw end 800psi

-

技术规范TECHNICAL SPECIFICATION

设计标准Design standard:DIN EN13709:2003

结构长度Face to face dimension:DIN EN558-1:1995

连接法兰Flanged ends:DIN EN1092-1:2002

对焊连接Velded ends:DIN EN12627

试验与检验Test&inspection:DIN EN12266:2003