dry barrel fire hydrant

Technical requirements:

1.Design:ANSI/AWWA C502

2.Nominal pressure:250PSI

3.Connecting thread of fire truck is 4.5-4NH

2 thread connector of hose is 2.5-7.5NH

4.Flange connector:DIN 2501 PN16/ASME B16.5 CLASS150

显示 225-240 个结果(共 509 个结果)

Technical requirements:

1.Design:ANSI/AWWA C502

2.Nominal pressure:250PSI

3.Connecting thread of fire truck is 4.5-4NH

2 thread connector of hose is 2.5-7.5NH

4.Flange connector:DIN 2501 PN16/ASME B16.5 CLASS150

Technical requirements:

1.Design:ANSI/AWWA C502

2.Nominal pressure:250PSI

3.One pumper nozzle 4.5-4NH thread.Two hose nozzles 2.5-7.5NH threads,other kinds of threads are available

4.Mechanical connector:AWWA/ANSI C153/A21.53 6″

5.Flange connector:DIN 2501 PN16/ASME B16.5 CLASS150

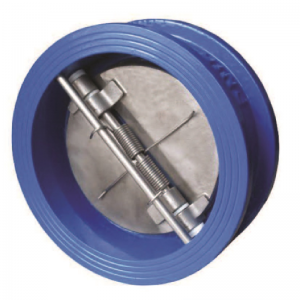

Design and Manufacture:API594

Face to face:EN558/ISO5752

Inspection:EN12266

Design and Manufacture:DIN3352

Face to face:DIN3202-K3/API 594

Flanged end: DIN 2501/BS 4504/ISO 7005-2 PN10/PN16,BS 10/AS 2129 Table D/E,JIS 2220 5K/10K,ASME B16.1 Class 125 & B16.42 Class 150

Inspection:DIN3230/ISO5208/JB-T9092

Designed to comply with API594.

Adopting dual plate design for efficient sealing.

Valve inspection and testing complywith API 598.

Available in Series F16 and Series F125.

Series F16 check valve compatible with GB,DIN,BS flanges.

Face to face according to ISO 5752 basic series16(wafer long).

F125 check valve compatiblewith ANSI 125/150 flanges.

Available in size 2″to 24″.

Available in wafer type body.

With many body/trim combinations,there is checkvalve to meet your application.

Designed to comply with API594.

Adopting dual plate design for efficient sealing.

Valve inspection and testing complywith API 598.

Available in Series F16 and Series F125.

Series F16 check valve compatible with GB,DIN,BS flanges.

Face to face according to ISO 5752 basic series16(wafer long).

F125 check valve compatiblewith ANSI 125/150 flanges.

Available in size 2″to 24″.

Available in wafer type body.

With many body/trim combinations,there is checkvalve to meet your application.

Series F402 valves designed to comply withBS5155.

Compatible with GB,DIN,BS andANSI125/150 flanges.

Face to face according toISO 5752 basic series 14 (long)/DIN 3202 part 1 series F4.

Adopting design of double-eccentric,the friction on sealing ring may be decreased to extendservice life.

One piece profile sealing resilient seat.

Available in size 4″to 48″.

Available with handles.manual gear operators,and electric or pneumaticactuators.

Design and Manufacture:JB/T8691,MSS SP-81

Face to face:GB/T15188.2,TAPPI TIS 405.8

Flange ends dimension:ANSI B 16.5,GB/T79-94

Inspection and Test:MSS SP-81,GB/T 13927

Design and Manufacture:JB/T8691,MSS SP-81

Face to face:GB/T15188.2,TAPPI TIS 405.8

Flange ends dimension:ANSI B 16.5,GB/T79-94

Inspection and Test:MSS SP-81,GB/T 13927

Design and Manufacture:JB/T8691,MSS SP-81

Face to face:GB/T15188.2,TAPPI TIS 405.8

Flange ends dimension:ANSI B 16.5,GB/T79-94

Inspection and Test:MSS SP-81,GB/T 13927

Design and Manufacture:JB/T8691,MSS SP-81

Face to face:GB/T15188.2,TAPPI TIS 405.8

Flange ends dimension:ANSI B 16.5,GB/T79-94

Inspection and Test:MSS SP-81,GB/T 13927

Design and Manufacture:JB/T8691,MSS SP-81

Face to face:GB/T15188.2,TAPPI TIS 405.8

Flange ends dimension:ANSI B 16.5,GB/T79-94

Inspection and Test:MSS SP-81,GB/T 13927

Design and Manufacture:JB/T8691,MSS SP-81

Face to face:GB/T15188.2,TAPPI TIS 405.8

Flange ends dimension:ANSI B 16.5,GB/T79-94

Inspection and Test:MSS SP-81,GB/T 13927

Design and Manufacture:JB/T8691,MSS SP-81

Face to face:GB/T15188.2,TAPPI TIS 405.8

Flange ends dimension:ANSI B 16.5,GB/T79-94

Inspection and Test:MSS SP-81,GB/T 13927