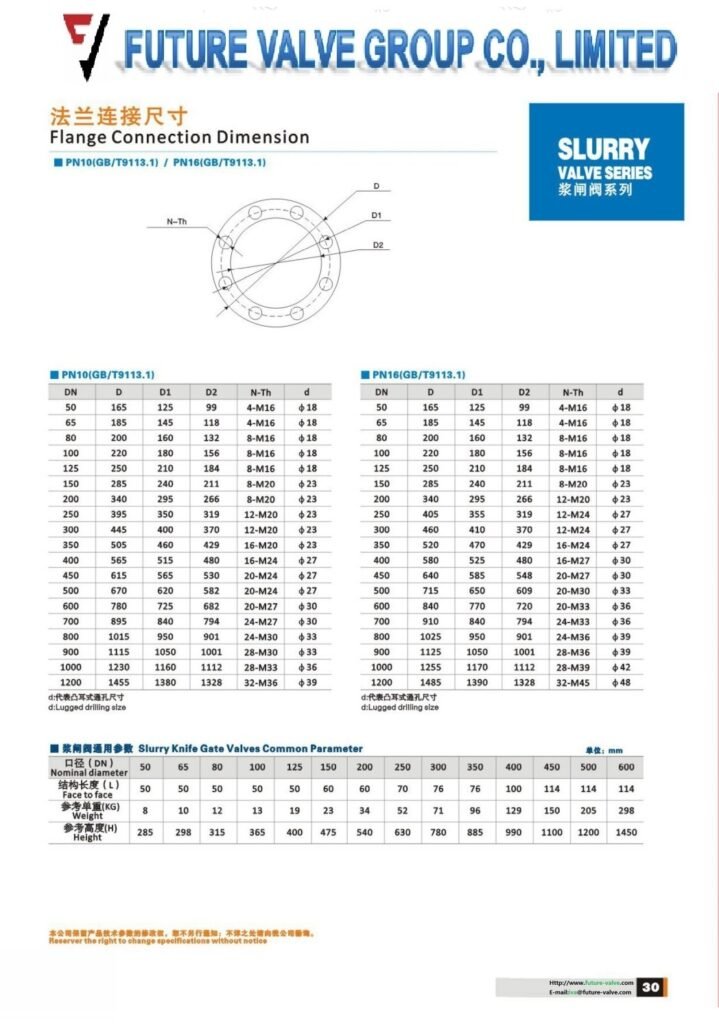

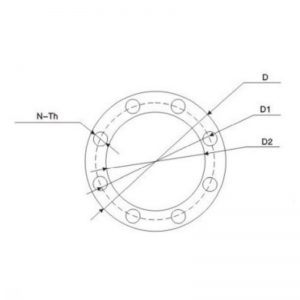

GBT9113.1 PN10 and PN16

Design and Manufacture:JB/T8691,MSS SP-81

Face to face:GB/T15188.2,TAPPI TIS 405.8

Flange ends dimension:ANSI B 16.5,GB/T79-94

Inspection and Test:MSS SP-81,GB/T 13927

描述

flange connection dimension GBT9113.1 PN10 and PN16

For plastic solids and high-viscosity slurries such as paper pulp, a specialty valve known as a knife gate valve is used to cut through the material to stop the flow. A knife gate valve is usually not wedge shaped and has a tapered knife-like edge on its lower surface.

DISTINCTIVE FEATURES

□ Wafer or Semi-lugged

■ Full Lugged or Flanged

□ Bonnetless Design

■ MSS SP-81 Complied

□ Cast Steel or Cast Iron

■ Soft Seat or Metal Seat

□ Uni or Bi Directional

■ API 6D & CE Certified

MAIN CHARACTERISTICS

FUTURE VALVE offer a broad line of universal knife gate valves covering resilient seat and metal to metal seat, ends connection in wafer, flanged and fully lugged which are widely used in various industries, including mining, power plant, urban sewage treatment, food and beverage, paper mill, petroleum, etc

DESIGN ADVANTAGES

Wafer or Fully Lugged bonnetless knife gate valves are with advantages of compact structure, reasonable design, material saving, reliable sealing, convenient operation, small volume, full passage flow, small flow resistance, small weight, easy installation and maintenance.

TECHNICALS & CAPABILITIES

• Sizes Ranges from 2″ thru 80″, DN50 thru DN2000

• Pressure Ratings: PN6, PN10, PN16, ANSI # Cl125 & Cl150

• Ends Connections available in Wafer ends, Semi-lug, Lug type, or Double Flanged,

• Materials: Cast Iron, Carbon Steel, Stainless Steel, Duplex SS, Al-bronze, or other special alloys.

• Operation: Manually lever or gear, Electric, Pneumatic or Hydraulic, Electric

• Standard compliance: MSS SP-81, ASME B16.10, ASME B16.5, ASME B16.47, ASME B16.34, AS 2129 T/D or T/E, BS 4504 T/D OR T/E, MSS SP-55, EN 1092

• Compact design, one piece integral cast body, chest and lugs

• Integral cast in gate wedges minimize flow obstructions

• High quality gate finish for optimum sealing

• High flow rates with low pressure drops

• Robust and compact mounting yoke made of steel with self aligning gland box

• Gland packing made of PTFE impregnated Fibres