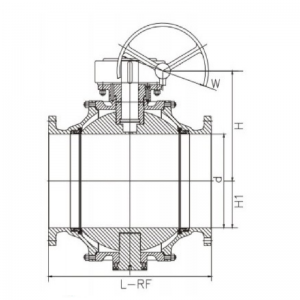

API Trunnion Ball Valve

Standards and specification

Design &manufacture: API 6D, API 608, ASME B16.34, ANSI AWWA C507,MSS SP-72, BS 5351, BS 6364, BFCI 70-2,ISO 5211,NACE MR0175

Connection ends: ASME B16.5, ASME B16.47,API 605, MSS SP-44,ISO7005-1,JIS B2238, BS 12627,ASME B16.25, ASME B16.11, BS 12760

Face to face dimension: ASME BI6.10, ISO 5752,BS 558,BS 12982

Testing inspection: API 598, API 6D, API 607, API 6FA, BS 6755, BS 12569, MSS SP-82, MSS SP-60

Normal pressure or rating: Class 150~Class2500,JIS 10K~20K,PN10~PN420

Normal diameter or bore: NPS 1/2~NPS10,DN15~DN250

Applicable temperature:-196℃~540℃

Operation type:manual,worm gear,pneumatic,electric

描述

Construction and features of trunnion ball valve

Seating structure

According to some special working conditions and customer”s requirement, we provide the trunnion ball valve with the Bi-sealing design structure i.e. seat sealing in front of the ball and seat sealing behind the ball, thus the reliable sealing of the valve is ensured because the valve can perform normally even if one of the effective sealing designs becomes lost due to the abnormal condition.

Fire safe design

In case of fire, the non-metal material parts such as seat sealing ring of PTFE, o-ring for the stem, and sealing gasket for body and bonnet, might be damaged due to high temperature As showed in the figure, our special design structure of secondary metal to metal or the graphite seal is provided for the trunnion ball valve to effectively prevent both internal and external leakage of the valve. This design can meet the requirement of API 607.

Anti blowout stem

Anti blowout structure is provided with for the stem, which is positioned by the up-end cap and screw, being guaranteed not to be blown-out by the medium even if even if at abnormal risen pressure in the cavity.

Anti-static design

The ball of the trunnion ball valve gets closed with each other through trunnion, adjusting cushion, and down-end cap, the passage of static electricity thus forms together with the valve, which may lead the static electrcity caused by sparks generated by friction between the ball and seat during on and off performance to the ground to prevent the possible of fire or explosion.