-

Body Material: Carbon Steel, Stainless Steel, Alloy Steel.

Normal Diameter: 2 Inch – 60 Inch (DN50-DN1500).

End Connection: BW, Flanged.

Pressure Range: 150 – 2500 LB (PN16-PN420).

Operation: Lever, Gearbox, Electric, Pneumatic, Electro Hydraulic Actuator, Gas Over Oil Actuator.

Working Temperature: -46℃-+200℃.

-

Design and Manufacture:BS5153

Face to face:BS5153

Flanged end:BS4504/BS table-D/E

Inspection:ISO5208

-

Design and Manufacture:JB/T8691,MSS SP-81

Face to face:GB/T15188.2,TAPPI TIS 405.8

Flange ends dimension:ANSI B 16.5,GB/T79-94

Inspection and Test:MSS SP-81,GB/T 13927

-

Design & manufacture: BS 1868-1873,ASME B16.34,API 6D

Face to Face:ASTM B16.10

Testing inspection: API 598,API 6D

Flanged end dimension: ASME B16.5,ASME B16.47A,ASME B16.47B,MSS SP-44,API 605

Butt-Welded end dimension: ASME B16.25

Pressure temperature ratings: ASME B16.34

Wall thickness dimension:API 600 and BS1868

-

Design and Manufacture:DIN3352

Face to face:DIN3202-F1/ISO5752

Flanged end: DIN2501/2532/EN 1092

Inspection:DIN3230/ISO5208/JB-T9092

-

Design and Manufacture:DIN3352

Face to face:DIN3202-F6/ISO5752

Flanged end: DIN2501/2532/EN 1092

Inspection:DIN3230/ISO5208/JB-T9092

-

Design & Manufacture:DIN EN 12516-1,BS EN 12516.1,BS EN 1868,EN12569

Face to Face Dimension:DIN EN558.1,BS EN 558-1

Flange Ends Dimension:BS EN 1092-1,DIN EN1092.1

BW End Dimension:EN12627

Test & Inspection: BS EN 12266,DIN N12266.1

-

TECHNICAL SPECIFICATION

Design standard:DIN EN13709:2003

Face to face dimension:DIN EN558-1:1995

Flanged ends:DIN EN1092-1:2002

Welded ends:DIN EN12627

Test & inspection:DIN EN12266:2003

-

Design and Manufacture:DIN

Face to face:

Flange Std:EN1092(DIN2501)

Inspection:EN12266

-

Design & manufacture: DIN 3840,BS EN 1868

Testing inspection: DIN3230,BS EN12569

Face to Face dimensions:DIN3202,EN558

Flanged end dimension: DIN2543,DIN2544,DIN2545,DIN2546,EN 1092-1

-

Design and Manufacture:API594

Face to face:EN558/ISO5752

Inspection:EN12266

-

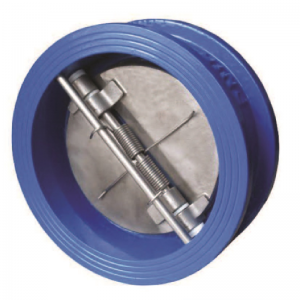

Designed to comply with API594.

Adopting dual plate design for efficient sealing.

Valve inspection and testing complywith API 598.

Available in Series F16 and Series F125.

Series F16 check valve compatible with GB,DIN,BS flanges.

Face to face according to ISO 5752 basic series16(wafer long).

F125 check valve compatiblewith ANSI 125/150 flanges.

Available in size 2″to 24″.

Available in wafer type body.

With many body/trim combinations,there is checkvalve to meet your application.

-

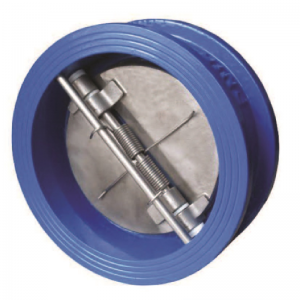

Designed to comply with API594.

Adopting dual plate design for efficient sealing.

Valve inspection and testing complywith API 598.

Available in Series F16 and Series F125.

Series F16 check valve compatible with GB,DIN,BS flanges.

Face to face according to ISO 5752 basic series16(wafer long).

F125 check valve compatiblewith ANSI 125/150 flanges.

Available in size 2″to 24″.

Available in wafer type body.

With many body/trim combinations,there is checkvalve to meet your application.

-

Design and Manufacture:DIN3352

Face to face:DIN3202-K3/API 594

Flanged end: DIN 2501/BS 4504/ISO 7005-2 PN10/PN16,BS 10/AS 2129 Table D/E,JIS 2220 5K/10K,ASME B16.1 Class 125 & B16.42 Class 150

Inspection:DIN3230/ISO5208/JB-T9092

-

Design and Manufacture:GOST,GB

-

1.Installed in both horizontal or vertical line with upward flow

2.Easier and faster to maintain and install